Fifty years after the beginning of the rechargeable lithium-ion battery, it’s simple to see its worth. It’s utilized in billions of laptops, cellphones, energy instruments, and automobiles. World gross sales high US $45 billion a yr, on their approach to greater than $100 billion within the coming decade.

And but this transformative invention took almost twenty years to make it out of the lab, with quite a few corporations in the US, Europe, and Asia contemplating the know-how and but failing to acknowledge its potential.

The primary iteration, developed by

M. Stanley Whittingham at Exxon in 1972, didn’t get far. It was manufactured in small volumes by Exxon, appeared at an electrical automobile present in Chicago in 1977, and served briefly as a coin cell battery. However then Exxon dropped it.

Numerous scientists around the globe took up the analysis effort, however for some 15 years, success was elusive. It wasn’t till the event landed on the proper firm on the proper time that it lastly began down a path to battery world domination.

Did Exxon invent the rechargeable lithium battery?

Akira Yoshino, John Goodenough, and M. Stanley Whittingham [from left] shared the 2019 Nobel Prize in Chemistry. At 97, Goodenough was the oldest recipient within the historical past of the Nobel awards.

Akira Yoshino, John Goodenough, and M. Stanley Whittingham [from left] shared the 2019 Nobel Prize in Chemistry. At 97, Goodenough was the oldest recipient within the historical past of the Nobel awards.

Jonas Ekstromer/AFP/Getty Photographs

Within the early Nineteen Seventies, Exxon scientists predicted that world oil manufacturing would peak within the yr 2000 after which fall into a gradual decline. Firm researchers had been inspired to search for oil substitutes, pursuing any method of power that didn’t contain petroleum.

Whittingham, a younger British chemist, joined the search at Exxon Analysis and Engineering in New Jersey within the fall of 1972. By Christmas, he had developed a battery with a titanium-disulfide cathode and a liquid electrolyte that used lithium ions.

Whittingham’s battery was in contrast to something that had preceded it. It labored by inserting ions into the atomic lattice of a bunch electrode materials—a course of known as intercalation. The battery’s efficiency was additionally unprecedented: It was each rechargeable and really excessive in power output. As much as that point, the most effective rechargeable battery had been nickel cadmium, which put out a most of 1.3 volts. In distinction, Whittingham’s new chemistry produced an astonishing 2.4 volts.

Within the winter of 1973, company managers summoned Whittingham to the corporate’s New York Metropolis places of work to look earlier than a subcommittee of the Exxon board. “I went in there and defined it—5 minutes, 10 on the most,” Whittingham informed me in January 2020. “And inside per week, they mentioned, sure, they wished to speculate on this.”

Whittingham’s battery, the primary lithium intercalation battery, was developed at Exxon in 1972 utilizing titanium disulfide for the cathode and metallic lithium for the anode.Johan Jarnestad/The Royal Swedish Academy of Sciences

Whittingham’s battery, the primary lithium intercalation battery, was developed at Exxon in 1972 utilizing titanium disulfide for the cathode and metallic lithium for the anode.Johan Jarnestad/The Royal Swedish Academy of Sciences

It regarded like the start of one thing large. Whittingham printed a

paper in Science; Exxon started manufacturing coin cell lithium batteries, and a Swiss watch producer, Ebauches, used the cells in a solar-charging wristwatch.

However by the late Nineteen Seventies, Exxon’s curiosity in oil alternate options had waned. Furthermore, firm executives thought Whittingham’s idea was unlikely to ever be broadly profitable. They washed their arms of lithium titanium disulfide, licensing the know-how to 3 battery corporations—one in Asia, one in Europe, and one in the US.

“I understood the rationale for doing it,” Whittingham mentioned. “The market simply wasn’t going to be large enough. Our invention was simply too early.”

Oxford takes the handoff

In 1976, John Goodenough [left] joined the College of Oxford, the place he headed improvement of the primary lithium cobalt oxide cathode.The College of Texas at Austin

In 1976, John Goodenough [left] joined the College of Oxford, the place he headed improvement of the primary lithium cobalt oxide cathode.The College of Texas at Austin

It was the primary of many false begins for the rechargeable lithium battery.

John B. Goodenough on the College of Oxford was the following scientist to choose up the baton. Goodenough was accustomed to Whittingham’s work, partially as a result of Whittingham had earned his Ph.D. at Oxford. But it surely was a 1978 paper by Whittingham, “Chemistry of Intercalation Compounds: Steel Friends in Chalcogenide Hosts,” that satisfied Goodenough that the forefront of battery analysis was lithium. [Goodenough passed away on 25 June at the age of 100.]

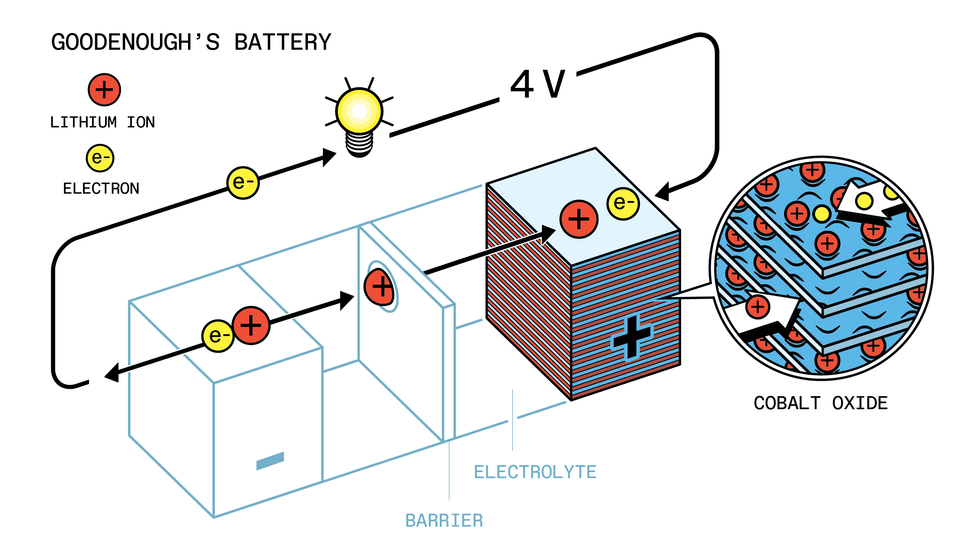

Goodenough and analysis fellow Koichi Mizushima started researching lithium intercalation batteries. By 1980, they’d improved on Whittingham’s design, changing titanium disulfide with lithium cobalt oxide. The brand new chemistry boosted the battery’s voltage by one other two-thirds, to 4 volts.

Goodenough wrote to battery corporations in the US, United Kingdom, and the European mainland in hopes of discovering a company associate, he recalled in his 2008 memoir, Witness to Grace. However he discovered no takers.

He additionally requested the College of Oxford to pay for a patent, however Oxford declined. Like many universities of the day, it didn’t concern itself with mental property, believing such issues to be confined to the industrial world.

Goodenough’s 1980 battery changed Whittingham’s titanium disulfide within the cathode with lithium cobalt oxide.Johan Jarnestad/The Royal Swedish Academy of Sciences

Goodenough’s 1980 battery changed Whittingham’s titanium disulfide within the cathode with lithium cobalt oxide.Johan Jarnestad/The Royal Swedish Academy of Sciences

Nonetheless, Goodenough had confidence in his battery chemistry. He visited the

Atomic Power Analysis Institution (AERE), a authorities lab in Harwell, about 20 kilometers from Oxford. The lab agreed to bankroll the patent, however provided that the 59-year-old scientist signed away his monetary rights. Goodenough complied. The lab patented it in 1981; Goodenough by no means noticed a penny of the unique battery’s earnings.

For the AERE lab, this could have been the final word windfall. It had completed not one of the analysis, but now owned a patent that might transform astronomically beneficial. However managers on the lab didn’t see that coming. They filed it away and forgot about it.

Asahi Chemical steps as much as the plate

The rechargeable lithium battery’s subsequent champion was

Akira Yoshino, a 34-year-old chemist at Asahi Chemical in Japan. Yoshino had independently begun to research utilizing a plastic anode—created from electroconductive polyacetylene—in a battery and was in search of a cathode to pair with it. Whereas cleansing his desk on the final day of 1982, he discovered a 1980 technical paper coauthored by Goodenough, Yoshino recalled in his autobiography, Lithium-Ion Batteries Open the Door to the Future, Hidden Tales by the Inventor. The paper—which Yoshino had despatched for however hadn’t gotten round to studying—described a lithium cobalt oxide cathode. Might it work along with his plastic anode?

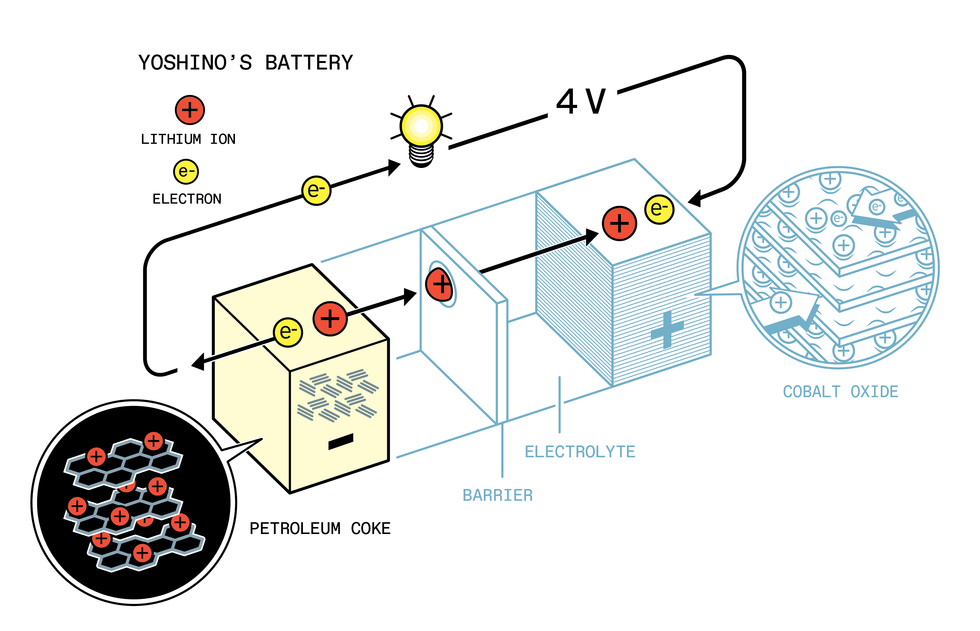

Yoshino, together with a small workforce of colleagues, paired Goodenough’s cathode with the plastic anode. Additionally they tried pairing the cathode with quite a lot of different anode supplies, largely created from various kinds of carbons. Finally, he and his colleagues settled on a carbon-based anode created from petroleum coke.

Yoshino’s battery, developed at Asahi Chemical within the late Eighties, mixed Goodenough’s cathode with a petroleum coke anode. Johan Jarnestad/The Royal Swedish Academy of Sciences

Yoshino’s battery, developed at Asahi Chemical within the late Eighties, mixed Goodenough’s cathode with a petroleum coke anode. Johan Jarnestad/The Royal Swedish Academy of Sciences

This alternative of petroleum coke turned out to be a serious step ahead. Whittingham and Goodenough had used anodes created from metallic lithium, which was risky and even harmful. By switching to carbon, Yoshino and his colleagues had created a battery that was far safer.

Nonetheless, there have been issues. For one, Asahi Chemical was a chemical firm, not a battery maker. Nobody at Asahi Chemical knew the right way to construct manufacturing batteries at industrial scale, nor did the corporate personal the coating or winding tools wanted to fabricate batteries. The researchers had merely constructed a crude lab prototype.

Enter Isao Kuribayashi, an Asahi Chemical analysis government who had been a part of the workforce that created the battery. In his e-book,

A Anonymous Battery with Untold Tales, Kuribayashi recounted how he and a colleague sought out consultants in the US who might assist with the battery’s manufacturing. One marketing consultant advisable Battery Engineering, a tiny agency based mostly in a transformed truck storage within the Hyde Park space of Boston. The corporate was run by a small band of Ph.D. scientists who had been specialists within the development of bizarre batteries. They’d constructed batteries for a bunch of makes use of, together with fighter jets, missile silos, and downhole drilling rigs.

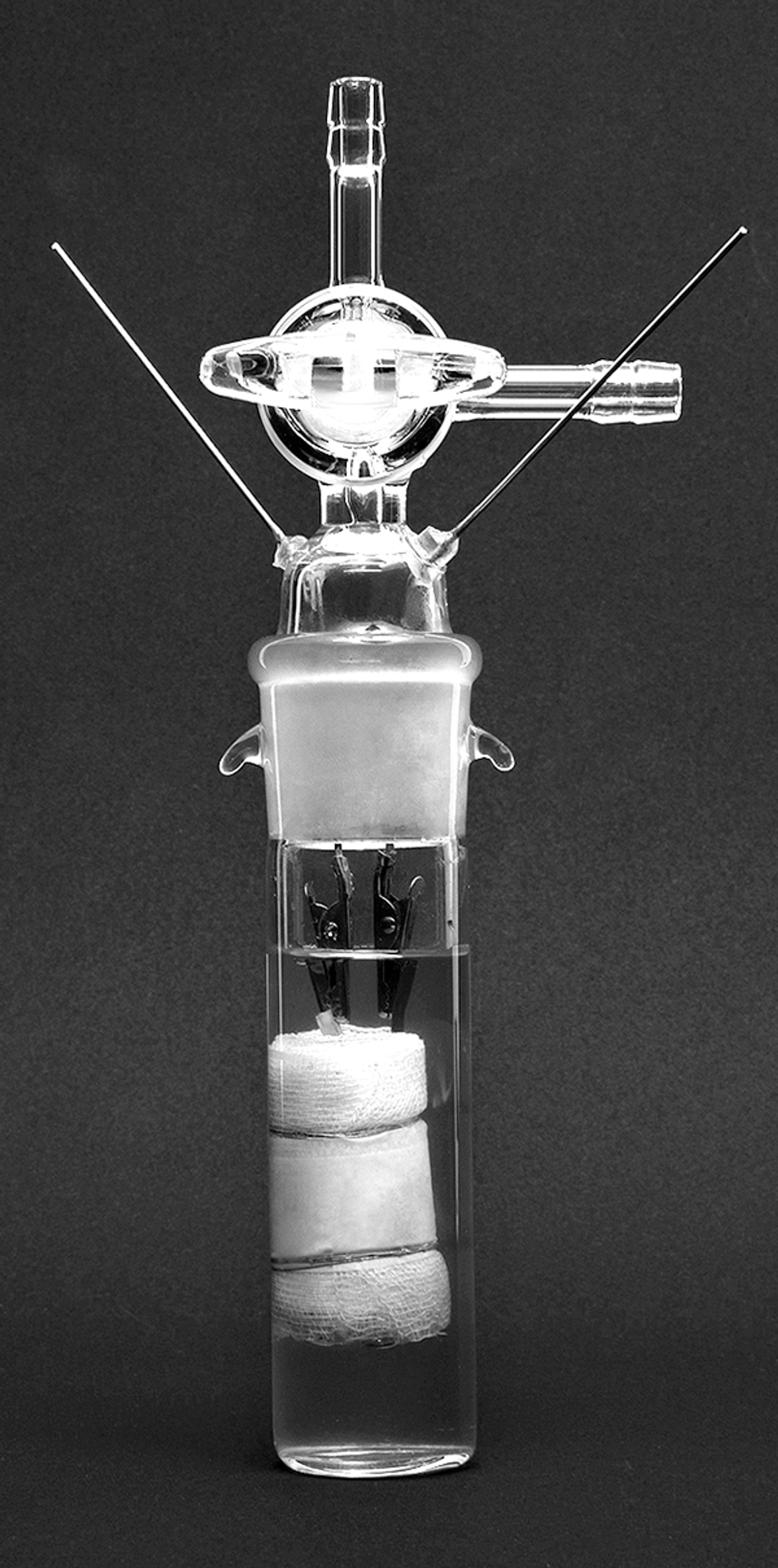

Nikola Marincic, working at Battery Engineering in Boston, remodeled Asahi Chemical’s crude prototype [below] into preproduction cells. Lidija Ortloff

Nikola Marincic, working at Battery Engineering in Boston, remodeled Asahi Chemical’s crude prototype [below] into preproduction cells. Lidija Ortloff

So Kuribayashi and his colleague flew to Boston in June of 1986, exhibiting up at Battery Engineering unannounced with three jars of slurry—one containing the cathode, one the anode, and the third the electrolyte. They requested firm cofounder

Nikola Marincic to show the slurries into cylindrical cells, like the type somebody would possibly purchase for a flashlight.

“They mentioned, ‘If you wish to construct the batteries, then don’t ask any extra questions,’” Marincic informed me in a 2020 interview. “They didn’t inform me who despatched them, and I didn’t need to ask.”

Kuribayashi and his colleague additional stipulated that Marincic inform nobody about their battery. Even Marincic’s workers didn’t know till 2020 that they’d participated within the development of the world’s first preproduction lithium-ion cells.

Marincic charged $30,000 ($83,000 in at the moment’s {dollars}) to construct a batch of the batteries. Two weeks later, Kuribayashi and his colleague departed for Japan with a field of 200 C-size cells.

Even with working batteries in hand, nevertheless, Kuribayashi nonetheless met resistance from Asahi Chemical’s administrators, who continued to worry shifting into an unknown enterprise.

Sony will get pulled into the sport

Kuribayashi wasn’t prepared to surrender. On 21 January 1987, he visited Sony’s

camcorder division to make a presentation about Asahi Chemical’s new battery. He took one of many C cells and rolled it throughout the convention room desk to his hosts.

Kuribayashi didn’t give many extra particulars in his e-book, merely writing that by visiting Sony, he hoped to “verify the battery know-how.”

Sony, nevertheless, did greater than “verify” it. By this time, Sony was contemplating growing its personal rechargeable lithium battery, in response to its

company historical past. When firm executives noticed Asahi’s cell, they acknowledged its huge worth. As a result of Sony was each a shopper electronics producer and a battery producer, its administration workforce understood the battery from each a buyer’s and a provider’s perspective.

And the timing was excellent. Sony engineers had been engaged on a brand new camcorder, later to be often called the

Handycam, and that product dearly wanted a smaller, lighter battery. To them, the battery that Kuribayashi offered appeared like a present from the heavens.

John Goodenough and his coinventor, Koichi Mizushima, satisfied the Atomic Power Analysis Institution to fund the price of patenting their lithium cobalt oxide battery however needed to signal away their monetary rights to take action.

John Goodenough and his coinventor, Koichi Mizushima, satisfied the Atomic Power Analysis Institution to fund the price of patenting their lithium cobalt oxide battery however needed to signal away their monetary rights to take action.

U.S. PATENT AND TRADEMARK OFFICE

A number of conferences adopted. Some Sony scientists had been allowed inside Asahi’s labs, and vice versa, in response to Kuribayashi. Finally, Sony proposed a partnership. Asahi Chemical declined.

Right here, the story of the lithium-ion battery’s journey to commercialization will get hazy. Sony researchers continued to work on growing rechargeable lithium batteries, utilizing a chemistry that Sony’s company historical past would later declare was created in home. However Sony’s battery used the identical important chemistry as Asahi Chemical’s. The cathode was lithium cobalt oxide; the anode was petroleum coke; the liquid electrolyte contained lithium ions.

What is obvious is that for the following two years, from 1987 to 1989, Sony engineers did the arduous work of reworking a crude prototype right into a product. Led by battery engineer

Yoshio Nishi, Sony’s workforce labored with suppliers to develop binders, electrolytes, separators, and components. They developed in-house processes for heat-treating the anode and for making cathode powder in massive volumes. They deserve credit score for creating a real industrial product.

Just one step remained. In 1989, certainly one of Sony’s executives known as the Atomic Power Analysis Institution in Harwell, England. The chief requested about one of many lab’s patents that had been gathering mud for eight years—Goodenough’s cathode. He mentioned Sony was concerned with licensing the know-how.

Scientists and executives on the Harwell lab scratched their heads. They couldn’t think about why anybody would have an interest within the patent “Electrochemical Cell with New Quick Ion Conductors.”

“It was not clear what the market was going to be, or how large it will be,” Invoice Macklin, an AERE scientist on the time, informed me. A number of of the older scientists even puzzled aloud whether or not it was acceptable for an atomic lab in England to share secrets and techniques with an organization in Japan, a former World Warfare II adversary. Finally, although, a deal was struck.

Sony takes it throughout the end line

Sony launched the battery in 1991, giving it the now-familiar moniker “

lithium-ion.” It shortly started to make its means into camcorders, then cellphones.

By that point, 19 years had handed since Whittingham’s invention. A number of entities had had the chance to take this know-how all the way in which—and had dismissed it.

First, there was Exxon, whose executives couldn’t have dreamed that lithium-ion batteries would find yourself enabling electrical autos to compete with oil in a giant means. Some observers would later contend that, by abandoning the know-how, Exxon had conspired to suppress a challenger to grease. However Exxon licensed the know-how to 3 different corporations, and none of these succeeded with it, both.

Then there was the College of Oxford, which had refused to pay for a patent.

Lastly, there was Asahi Chemical, whose executives struggled with the choice of whether or not to enter the battery market. (Asahi lastly acquired into the sport in 1993, teaming up with Toshiba to make lithium-ion batteries.)

Sony and AERE, the entities that gained probably the most financially from the battery, each benefitted from luck. The Atomic Power Analysis Institution paid solely authorized charges for what turned out to be a beneficial patent and later needed to be reminded that it even owned the patent. AERE’s income from its patent are unknown, however most observers agree that it reaped a minimum of $50 million, and presumably greater than $100 million, earlier than the patent expired.

Sony, in the meantime, had acquired that fortuitous go to from Asahi Chemical’s Kuribayashi, which set the corporate on the trail towards commercialization. Sony offered tens of hundreds of thousands of cells after which sublicensed the AERE patent to greater than two dozen different Asian battery producers, which made billions extra. (In 2016, Sony

offered its battery enterprise to Murata Manufacturing for 17.5 billion yen, roughly $126 million at the moment).

Not one of the unique investigators—Whittingham, Goodenough, and Yoshino—acquired a minimize of those income. All three, nevertheless, shared the

2019 Nobel Prize in Chemistry. Sony’s Yoshio Nishi, by then retired, wasn’t included within the Nobel, a call he criticized at a press convention, in response to the Mainichi Shimbun newspaper.

Looking back, lithium-ion’s early historical past now seems to be like a story of two worlds. There was a scientific world and a enterprise world, they usually seldom overlapped. Chemists, physicists, and supplies scientists labored quietly, sharing their triumphs in technical publications and on overhead projectors at conferences. The industrial world, in the meantime, didn’t look to school scientists for breakthroughs, and failed to identify the potential of this new battery chemistry, even these advances made by their very own researchers.

Had it not been for Sony, the rechargeable lithium battery may need languished for a lot of extra years. Virtually actually, the corporate succeeded as a result of its specific circumstances ready it to grasp and admire Kuribayashi’s prototype. Sony was already within the battery enterprise, it wanted a greater battery for its new camcorder, and it had been toying with the event of its personal rechargeable lithium battery. Sony engineers and managers knew precisely the place this puzzle piece might go, recognizing what so many others had ignored. As Louis Pasteur had famously acknowledged greater than a century earlier, “Probability favors the ready thoughts.”

The story of the lithium-ion battery reveals that Pasteur was proper.

This text seems within the August 2023 print subject as “The Lithium-ion Battery’s Lengthy and Winding Highway.”

From Your Web site Articles

Associated Articles Across the Internet